Design | Engineering | Equipment Manufacturing API Licenses & Certifications – 6A, 16A, 20E, ASME, CRN & ISO

Elastomer Manufacturing | Global Repair & Remanufacturing(API 16AR) | Global Distribution

Pulsation-Dampeners

(Asme-U)ASME U STAMPED │ ABS │ CRN │ DNV

A Pulsation Dampener is an accumulator designed to absorb pressure pulsations created by reciprocating pumps. Pulsation Dampeners are used to reduce wear and tear on all system components including the pump.

Pulsation dampeners are critical equipment in the oil and gas industry for their ability to stabilize pressure fluctuations, safeguard equipment, and enhance safety. It helps in mitigating pressure surges and enhance the lifespan of critical components, improve operational efficiency, reduce vibration and noise.

Moreover, these pulsation dampeners play a pivotal role in ensuring consistent and controlled fluid flow, contributing to safer, more efficient, and environmentally compliant oil and gas operations.

INTEGRATED® is a leading Original Equipment Manufacturer and specializes in the production of Pulsation Dampeners designed for utilization with a wide range of reciprocating pumps across diverse industries, including Oilfield Services (Workover, Drilling, Production – Suction & Discharge, Fluid End Pumping, and Pipeline) in diverse industries including mining, petrochemical, and reverse osmosis markets.

Additionally, Integrated manufactures upon request based on product catalogs that detail the available options for each of the Pulsation Dampener sizes, catering to the specific needs and preferences of their clientele.

PD Product catalogs are available upon request that offer options on each of the PD sizes below.

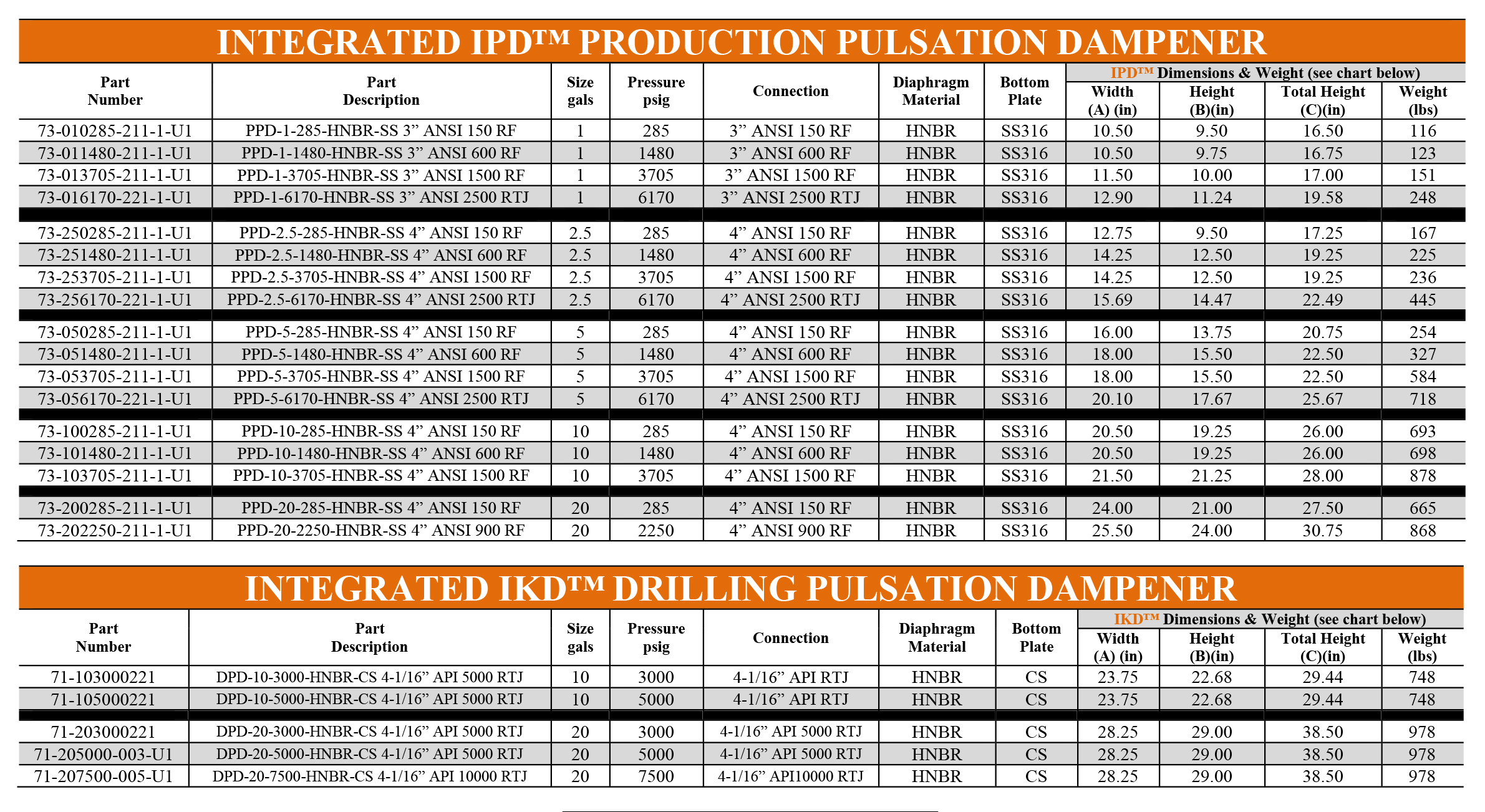

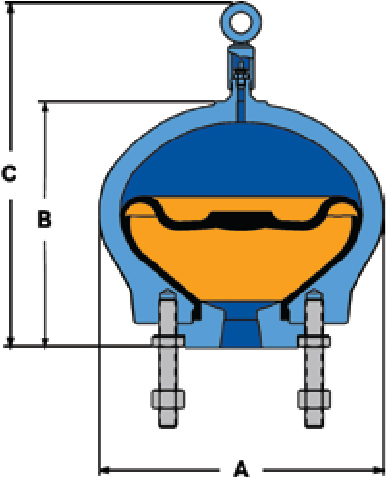

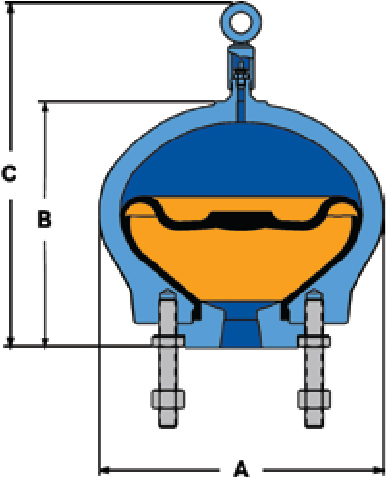

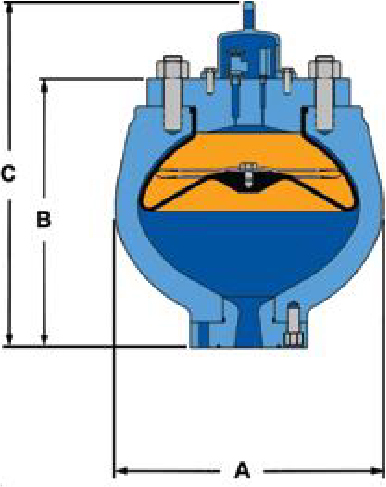

IPD™ PRODUCTION PULSATION DAMPENER DIMENSIONS & WEIGHTS

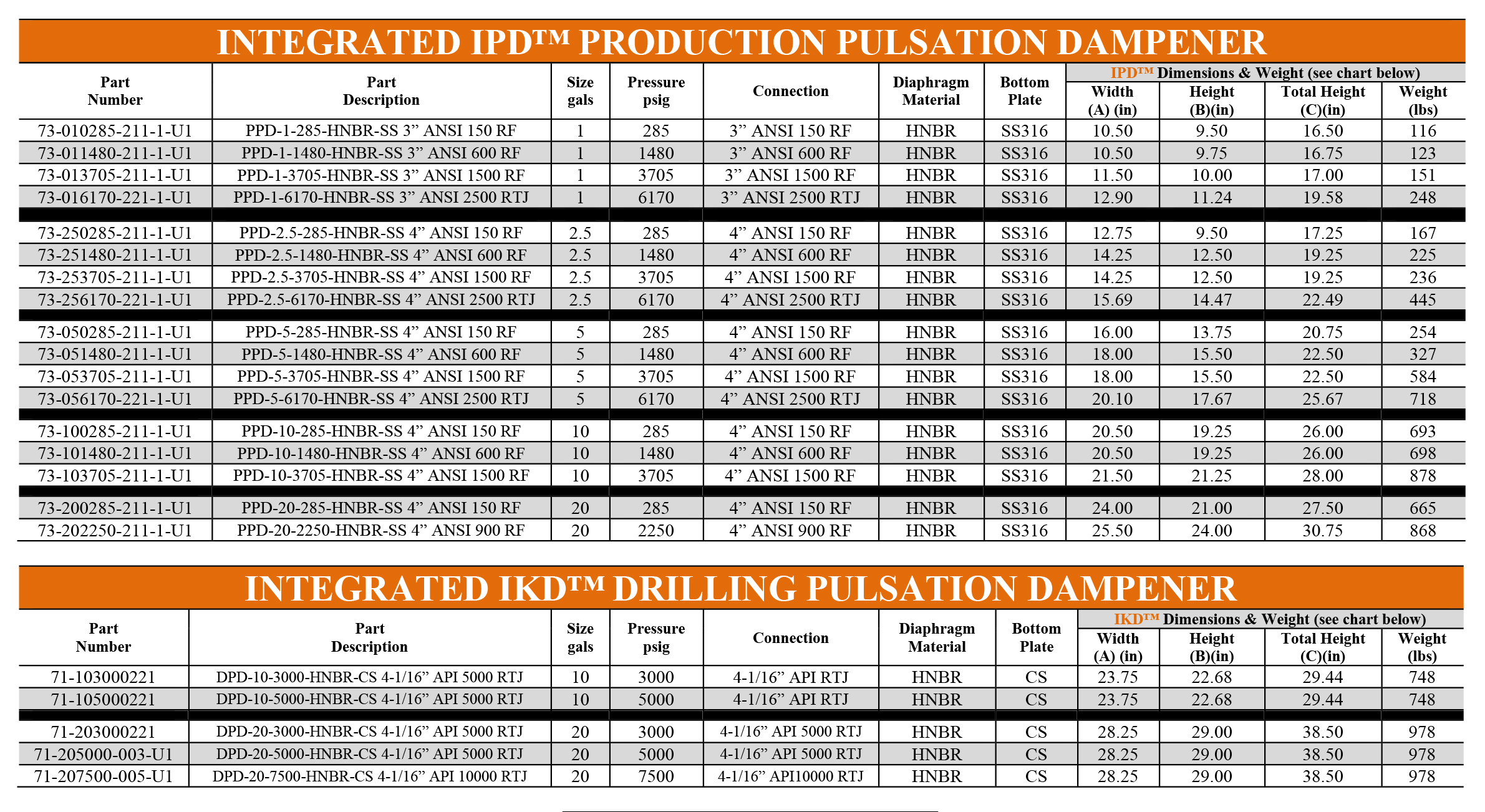

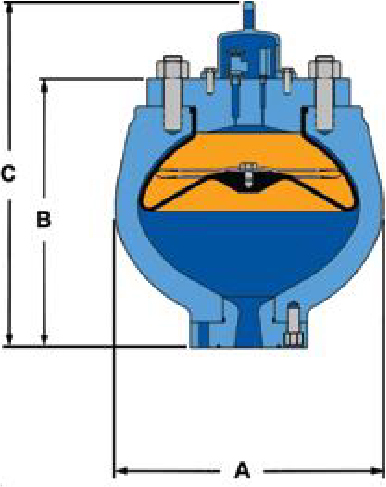

IKD™ DRILLING PULSATION DAMPENER DIMENSIONS & WEIGHTS

SIZING AND SELECTION OF PULSATION DAMPENERS

Pulsation Dampener selection is a critical process that requires a thorough knowledge of a pressure system, the system components, and the fluid characteristics.

There are two main types of pulsation dampeners: bladder dampeners and piston dampeners. Though bladder dampeners are more commonly used and are less expensive, piston dampeners are better suited for high pressures, temperatures, or corrosive or abrasive fluids. This has to be kept in mind before selecting the pulsation dampener.

The size of the pulsation dampener depends on the flow rate and pressure of the system, in addition to the required level of pulsation attenuation.

Additionally, the material of construction must be compatible with the fluid being pumped and the operating environment. The pulsation dampener must also be pre-charged to a pressure that is slightly below the minimum operating pressure of the system.

Please consult your integrated representative for assistance in making sure the Pulsation Dampener you select is right for your specific application.