Design ǀ Engineering ǀ OEM Equipment Manufacturing API Licenses (6A, 16A, 16C, 20E, ASME U) and Certifications (API Q1 & ISO)

OEM Elastomer Manufacturing ǀ Global Repair & Remanufacturing (OEM & API 16AR) ǀ Global Distribution

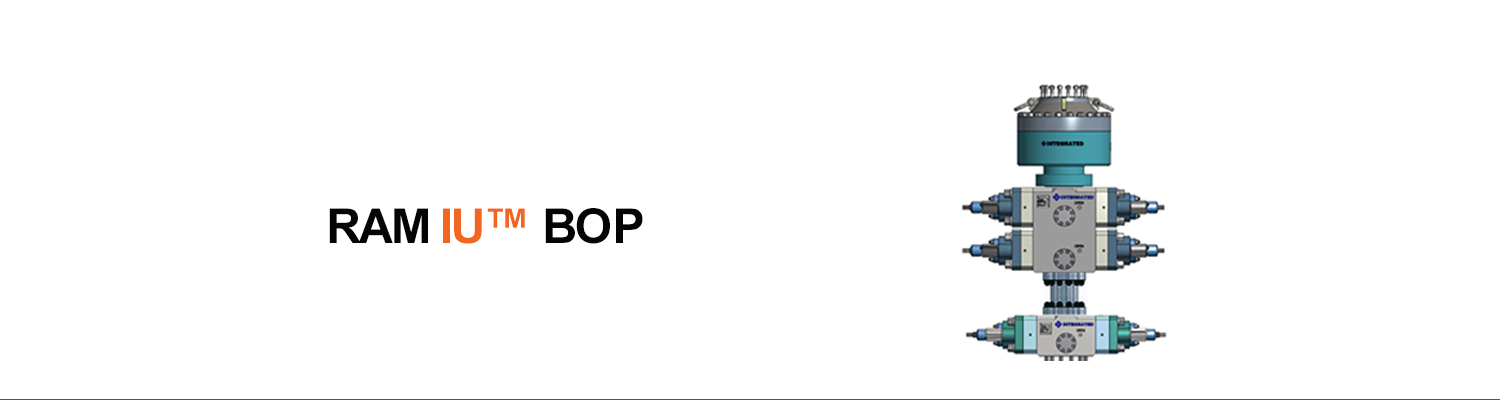

RAM IU™ BOP

The INTEGRATED® Model IU™ Ram Type Blowout Preventer (BOP) is used to contain wellbore pressure in land and platform drilling operations. The rams in IU™ BOP are hydraulically operated and pressure energized. Wellbore pressure acts on the rams to increase sealing force and maintain the wellbore seal in the event of hydraulic pressure loss. As the wellbore pressure increases, seal integrity is improved.

SPECIFICATIONS

- Application: Onshore

- Bore sizes and working pressures

- - 7-1/16” - 3,000, 5,000, 10,000 & 15,000 psi | 11” – 3,000, 5,000 & 10,000 psi | 13-5/8” – 3,000, 5,000 & 10,000 psi

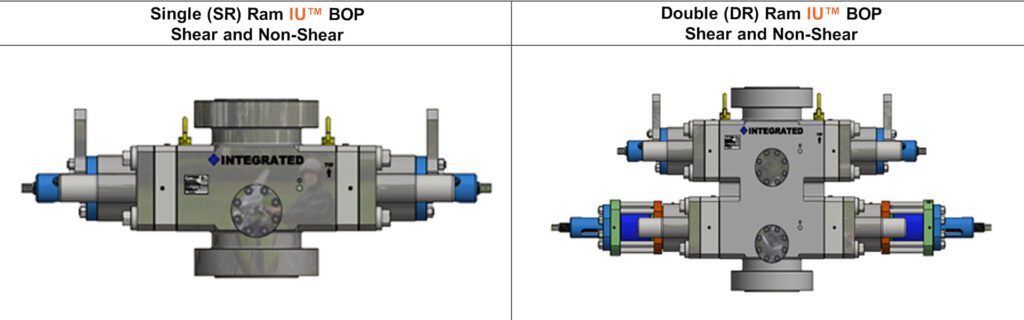

- Body styles: Single | Double

- Internal Bolting is as per API 20E (after April 2018)

- Designed and manufactured to ISO 13533 (API 16A) for Drill-through

- Designed as standard to ISO 15156-1 (NACE-0175) for use in hydrogen sulfide environments

- Fully Forged AISI or F22 75k

- Xylan coated internals for operational performance and corrosion control

- Wellbore fluid wetted dynamic sealing surfaces are hard faced, providing durable sealing surfaces that protect the integrity of the low alloy steel structure even after minor marring of the hard facing.

- Manual Ram Locking device

- Top & Bottom Connection Options: Studded x Studded, Studded x Flanged, Flanged x Studded or Flanged x Flanged)

- Outlets: Studded or Flanged. Standard: 7-1/16” – 2-1/16” | 11” – 3-1/16” | 13-5/8” – 4-1/16”