Design ǀ Engineering ǀ OEM Equipment Manufacturing API Licenses (6A, 16A, 16C, 20E, ASME U) and Certifications (API Q1 & ISO)

OEM Elastomer Manufacturing ǀ Global Repair & Remanufacturing (OEM & API 16AR) ǀ Global Distribution

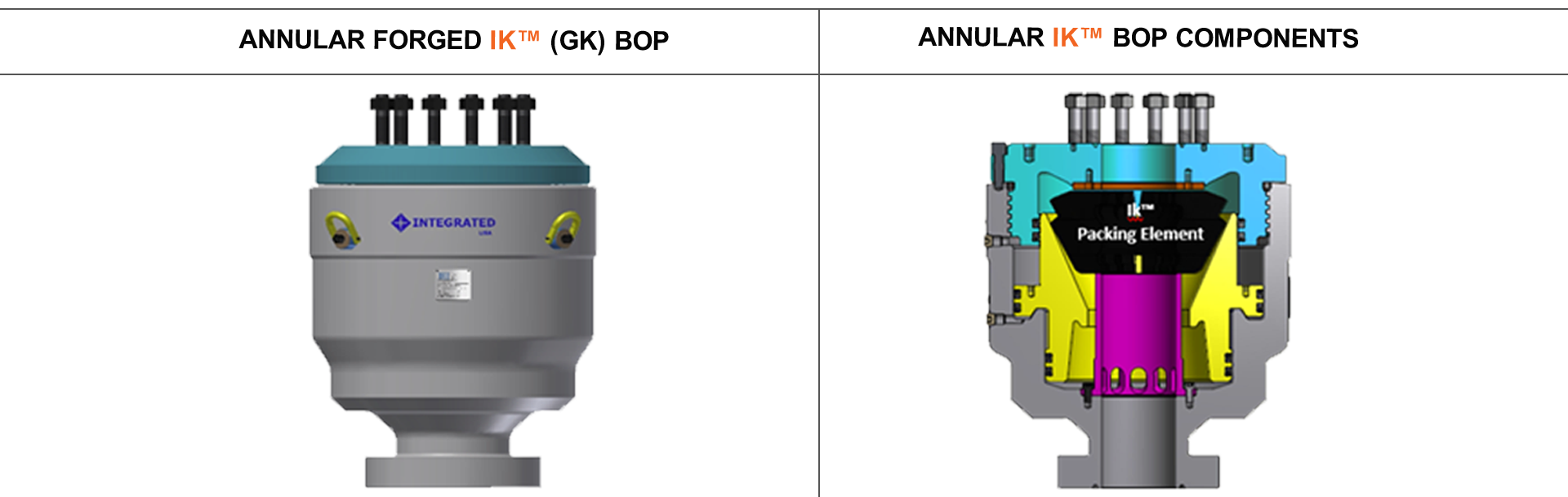

ANNULAR IK™ (GK) BOP

The Integrated Model IK™ (GK) Annular Type Blowout Preventer is field-tested and proven design that has dependability in well servicing and drilling applications. Simple design that features only two moving parts (piston and packing unit) which control for wear and maintenance. A replaceable wear plate that eliminates metal-to-metal contact between the packing element inserts and the BOP lid. The packing element allows closure on drilling pipe, tool joints or tubing and wireline as well as the open hole.

The INTEGRATED® IK™ Annular Blowout Preventer (BOP), is a dependable and versatile solution for drilling and well servicing related applications.

Its straightforward design, comprising just two mobile components (a piston and a sealing unit), guarantees effective control while reducing the need for maintenance and minimizing wear. The IK™ BOP has a replaceable wear plate that eliminates metal-to-metal contact between the packing element inserts and the BOP lid. With the packing element enabling closure on various tools, including drilling pipe, tool joints, tubing, wireline, and open holes, the IK™ Annular BOP is a reliable and efficient choice for drilling operations.

SPECIFICATIONS

- Application: Onshore, Inland Waters and above water line Offshore

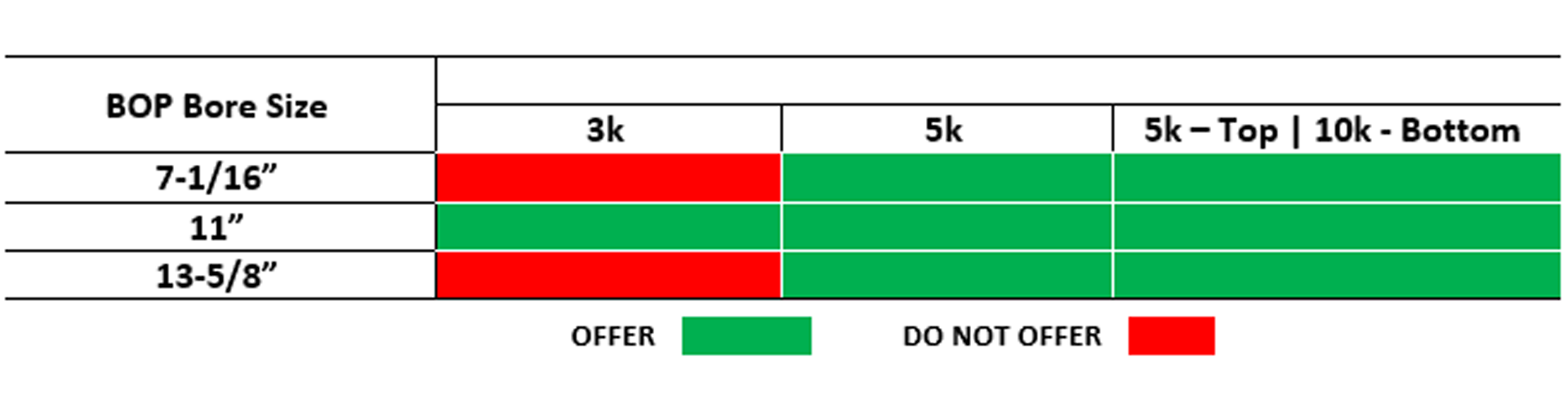

- Bore sizes and working pressures:

- Designed and manufactured to ISO 13533 (API 16A) for Drill-through equipment

- API 16A Monogramed Latest Edition

- Designed as standard to ISO 15156-1 (NACE MR-0175) for use in hydrogen sulfide environments (H2S)

- Material: Fully Forged AISI 4130, 75kk

- Temperature Class: T-20 │ 250

- Non-Metallic Seal Temperature Rating: BGB

- Standard Packing Element Temperature (T20): 40oF to 180oF

- Quality Level: PR1

- Xylan coated internals for operational performance and corrosion control

- Standard operation pressure of 1500 psi

- Ring Grooves are standard carbon steel. Other option is 625 Inconel Inlay (as per API 16A Edition 4)

- Standard connection configuration: Studded Top x Flanged Bottom

- IK™ Packing Element materials offered: NR (Natural) and NBR (Nitrile)