Design ǀ Engineering ǀ OEM API License Equipment Manufacturing ǀ OEM & After Market Elastomer Manufacturing | Global Repair & Remanufacturing ǀ Global Distribution

• API 6A • API 16A • API 16AR • API 16C • API 20E • ASME U • CE & CRN • API Q1 • ISO 9001-2015

Standpipe

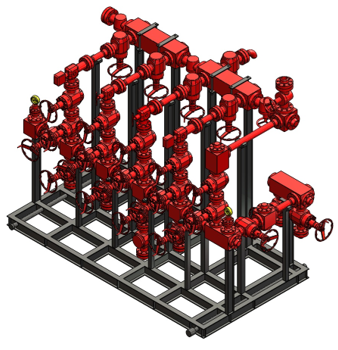

INTEGRATED® standpipe manifold is installed downstream of the mud pumps with the purpose of diverting the flow of drilling fluids toward the drill line or drill string. An adjustable choke can be installed to bleed pressure off the drillpipe, to reduce shock when breaking circulation in wells where loss of circulation is a problem, and to bleed off pressure between BOPs during stripping operations. Pressure ratings up to 7,500 psi are available.

INTEGRATED® Stand Pipe Manifolds are manufactured in our API Certified Plant. The INTEGRATED® Stand Pipe Manifolds consists of valves, pressure gauges, line pipes and chokes when requested.

- General Specifications:

- • Connections: Hammer, Flanged or Butt Welded

- • Either single or dual designs

- • Standard working pressures of 5,000 to 7,500 psi

- • Either free standing or with support frame

- • API 6A, API 16C Monogrammed components

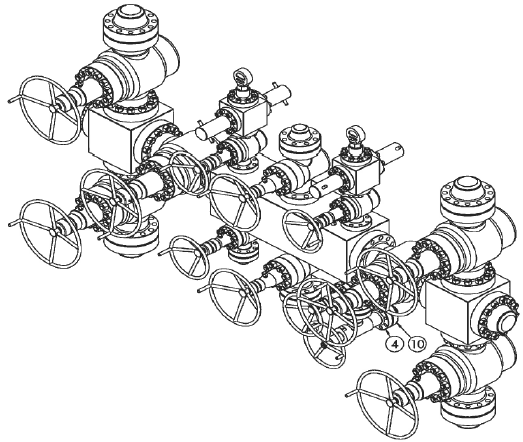

- Typical Configuration:

- • Flanged to Flange Standpipe Manifold

- • Weld up or 1202 Connections

- Standard Size Range:

- •2-1/16” – 5k to 4-1/16” – 7.5k

- Custom Size Range:

- • 5-1/8” – 5k to 7-1/16”

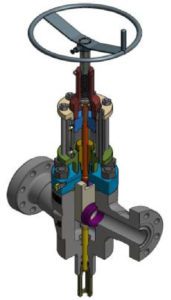

The success of our manifold system is INTEGRATED®’s DrillFLO PR2 andPSL3G Tested “Bi-directional” GateValve. DrillFLO™s Single SeatDesign high-quality valve.

- Temperature Class: P-X

- Qualification Level: PR2 (Appendix F Qualified)

- Material Class (trim): Up to HH

- Forged Construction

- Full Bore (internally Flushed)

- NACE MR-0175