Design ǀ Engineering ǀ OEM Equipment Manufacturing API Licenses (6A, 16A, 16C, 20E, ASME U) and Certifications (API Q1 & ISO)

OEM Elastomer Manufacturing ǀ Global Repair & Remanufacturing (OEM & API 16AR) ǀ Global Distribution

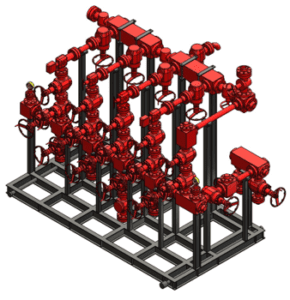

Manifolds

INTEGRATED® Manifolds are a customized arrangement of piping or API 6A valves and API 16C chokes designed to control, distribute, and typically monitor fluid flow during well operations. Manifolds are often configured for specific functions such as Choke & Kill manifold used in well control operations, a Standpipe manifold is utilized to divert the flow of drilling fluids toward the drill line or drill string, a Squeeze manifold used in cementing work, a Frac manifold for directing treatment fluid. In each case, the functional requirements of the operation have been addressed in the configuration of the manifold and the degree of control and instrumentation required.

Choke & Kill Manifold

INTEGRATED® offers a customized (based on client specifications) manifolds to manage well pressure during drilling operations by diverting flow through a series of valves and chokes.

Standpipe Manifold

INTEGRATED® standpipe manifold is installed downstream of the mud pumps with the purpose of diverting the flow of drilling fluids toward the drill line or drill string.

Other types of manifolds

Cement Manifolds

INTEGRATED® cement manifolds are designed and manufactured to customer requirements in accordance with the recognized oilfield equipment standards. The cement manifold is installed downstream of the cement unit with the purpose of diverting the flow of cement slurry during cementing operations.

General Specifications

- Pressure Rating: Up to 15,000 psi

- Connection: Hammer Unions or Flanges

- API 6A Plug Valves

- Either free standing or with support frame

- API 6A, API 16C Monogrammed components

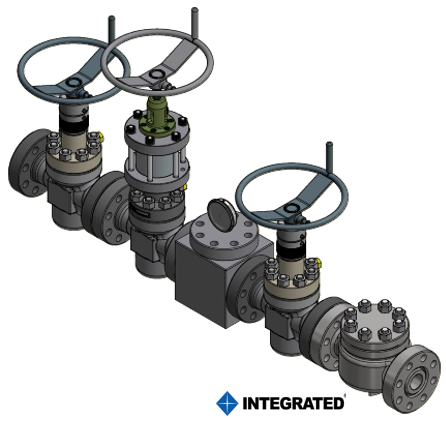

Kill Wing Valve Manifold

INTEGRATED® Kill Wing Valve manifolds (Left Hand Valve) primary used for injection of fluids such as corrosion inhibitors or methanol or for temporary surface flow used in drillstem testing.

Frac Manifold

INTEGRATED® Frac manifold is an arrangement of flow fittings and valves located between the Frac Pump header and the frac tree. From the Frac manifold, individual fac supply lines are installed to the device (typically a Goat Heads / Frac Heads) atop the wells. This allows re-direction of the frac fluids to be moved to the next well ready for stimulation. This process is called Zipper Fracturing and it can provide for nearly continuous utilization of the frac equipment and crews.

General Specifications

- Pressure Rating: Up to 15,000 psi

- Product Specification Level: PSL 1 or 2

- Temperature Range: P-U

- Normal Sizes: 4-1/16”, 5-1/8” or 7-1/16”

- Typically skid mounted