Design ǀ Engineering ǀ OEM Equipment Manufacturing API Licenses (6A, 16A, 16C, 20E, ASME U) and Certifications (API Q1 & ISO)

OEM Elastomer Manufacturing ǀ Global Repair & Remanufacturing (OEM & API 16AR) ǀ Global Distribution

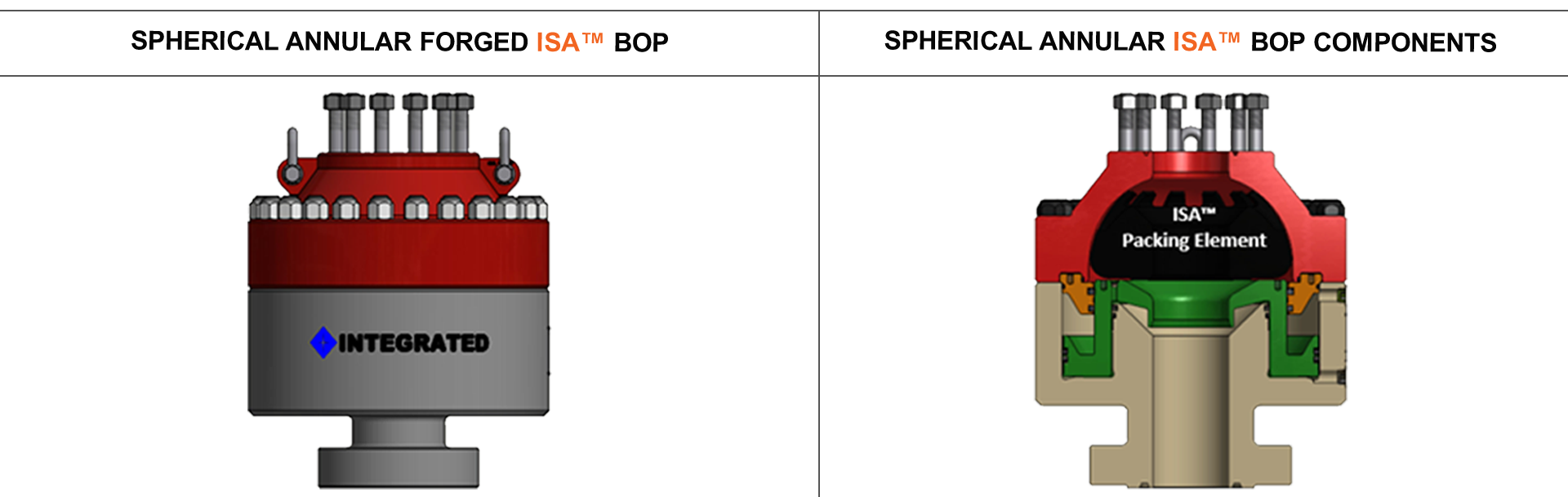

SPHERICAL ANNULAR ISA™ BOP

The Integrated Model ISA™ Spherical Annular Type Blowout Preventer is a hydraulic operated device designed for well pressure control during workover, snubbing and drilling operations. Simplistic design, ease of maintenance and field proven reliability … Integrated’s ISA™ Packing Element can close on almost any shape or size tubing, casing, drill pipe, drill collars, tool joints, wireline, and coiled tubing in the well bore or completely seal off (CSO) of the open bore. It is ideal for stripping tubing, pipe, and wireline.

The INTEGRATED® ISA™ Spherical Annular Blowout Preventer (BOP) ensures top-tier well pressure control for drilling, workover and snubbing.

Its simple and compact design guarantees easy maintenance and reliability. The design with minimum moving parts provides excellent repeatability in positive sealing.

Its versatility is a game-changer, with an added advantage of inhouse manufactured Packing element. Whether stripping tubing, pipe, or wireline, the INTEGRATED® ISA™ Packing Element is your trusted ally. Elevate your operations with the INTEGRATED® Model ISA™ Spherical Annular BOP – where simplicity meets unmatched performance.

SPECIFICATIONS

- Application: Onshore, Inland Waters and above water line Offshore

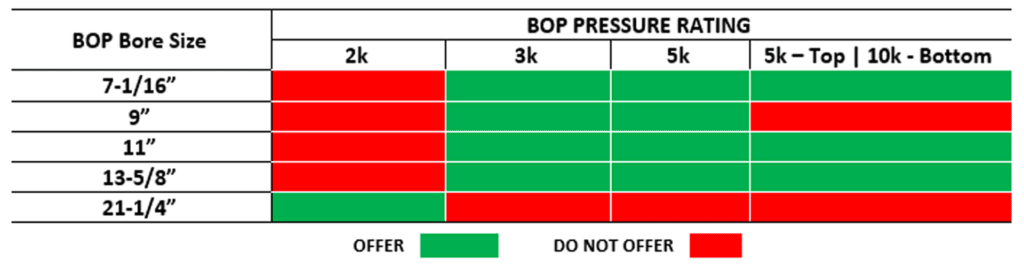

- Bore sizes and working pressures:

- Designed and manufactured to ISO 13533 (API 16A) for Drill-through equipment

- API 16A Monogramed Latest Edition

- Designed as standard to ISO 15156-1 (NACE MR-0175) for use in hydrogen sulfide environments (H2S)

- Material: Fully Forged AISI 4130, 75k

- Temperature Class: T-20 │ 250

- Non-Metallic Seal Temperature Rating: BGB

- Temperature Class: T-20 / 250

- Non-Metallic Seal Temperature Rating: BGB

- Standard Packing Element Temperature (T20): 40oF to 180oF

- Quality Level: PR1

- Xylan coated internals for operational performance and corrosion control

- Ring Grooves are standard carbon steel. Other option is 625 Inconel Inlay (as per API 16A Edition 4)

- Standard connection configuration: Studded Top x Flanged Bottom

- ISA™ Packing Element materials offered: NR (Natural), NBR (Nitrile) and HNBR (Hydrogenated Nitrile)